PERSPECTIVE

Technological and environmental challenges of Arctic shipping—a case study of a fictional voyage in the Arctic

Lars-Henrik Larsen,1 Beate Kvamstad-Lervold,2 Kjetil Sagerup,1 Victoria Gribkovskaia,2 Alexei Bambulyak,1 Rune Rautio1 & Tor Einar Berg2

1 Akvaplan-niva, Fram Centre, NO-9296 Tromsø, Norway

2 Marintek, PO Box 4125, Valentinslyst, NO-7450 Trondheim, Norway

Abstract

Shipping in Arctic seas is challenging and poses an environmental risk. This paper presents a fictional case involving a multipurpose supply vessel transporting one large object (a 750-tonne compressor) and 24 containers loaded with chemicals and equipment for use by the petroleum industry in western Siberia. With technical details representative of vessels navigating the Arctic today, the fictitious ship Oleum has an ice class sufficient for navigating unaccompanied in the Barents and Kara seas, so no assistance is in range when, in late October, clogged fuel filters cause engine failure and the vessel eventually drifts ashore. Heeling over, Oleum loses both cargo and marine diesel oil. The scenario includes a successful helicopter rescue of the 16 crewmembers and a partial recovery of oil and chemicals by booms and skimmers. Recovery of chemicals with physical properties not allowing mechanical collection is not attempted. The scenario ends as the abandoned wreck is broken down at the stranding location, and containers rupture and discharge their cargo. The scenario postulates a moderate and short-lived environmental impact. The most visible effects of the grounding are the hull itself, the compressor and the spreading effects and degradation of oil and chemicals unmanageable for the clean-up operations.

Keywords

Arctic shipping; technology; scenario; grounding; Northern Sea Route; environmental impact.

Citation: Polar Research 2016, 35, 27977, http://dx.doi.org/10.3402/polar.v35.27977

Copyright: © 2016 L.-H. Larsen et al. This is an Open Access article distributed under the terms of the Creative Commons Attribution-NonCommercial 4.0 International License, permitting all non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Published: 26 May 2016

Correspondence to: Lars-Henrik Larsen, Akvaplan-niva, Fram Centre, NO-9296 Tromsø, Norway. E-mail: lars@akvaplan.niva.no

To access the supplementary material for this article, please see the supplementary file under Article Tools, online.

Assessing the potential outcomes of a variety of options through the analysis of one or more fictitious scenarios is a valuable tool for assessing and predicting human influence on nature and ecosystems. The scenario method is a robust tool for asking “what if” questions in planning for the future (Duinker & Greig 2007). Here, a scenario approach is applied to the context of Arctic shipping, with the aim of describing a chain of events that is as realistic as possible. This involves a vessel on a realistic voyage and a set of known (planned) and unplanned events, influencing the outcome. The discussion covers technological and environmental issues of Arctic shipping as exemplified by the scenario.

The vessel, voyage, time of the year and cargo were chosen to represent a type of well-established navigation expected to increase in the Barents and Kara seas, as the industry of petroleum exploration and raw material extraction evolves (Arctic Council 2009). Oil and gas operations will move northwards along the coast of Arctic Europe and Asia and the need for seaborne supplies will increase as production grows; the export of oil, gas and other raw materials by ship will increase. As the Arctic Sea ice cover recedes, both new and existing shipping routes will become ice-free and expectations for increased transport along the North-east Passage, among other routes, are high (Schoyen & Brathen 2011; Smith & Stephenson 2013; Stephenson et al. 2013). Increased traffic in the Arctic will lead to an increased risk of accidents and thereby also a larger number of SAR operations. In general, this raises important questions concerning SAR and OSR operations and communication infrastructure.

Abbreviations in this article

GEO: geostationary satellites

GPS: Global Positioning System

HF/MF: high frequency/medium frequency radio

HOCNF: Harmonized Offshore Chemical Documentation Format

MDO: marine diesel oil

NSR: Northern Sea Route

NSRA: Russian NSR Administration

OSR: oil spill response

PAH: polycyclic aromatic hydrocarbons

SAR: search and rescue

VHF: very high frequency radio

The objective of this paper is to outline aspects of navigation, communication, SAR operation and clean-up actions using the scenario of a vessel sailing from a port in Europe towards a port in northern Russia.

The case

The ship and her cargo

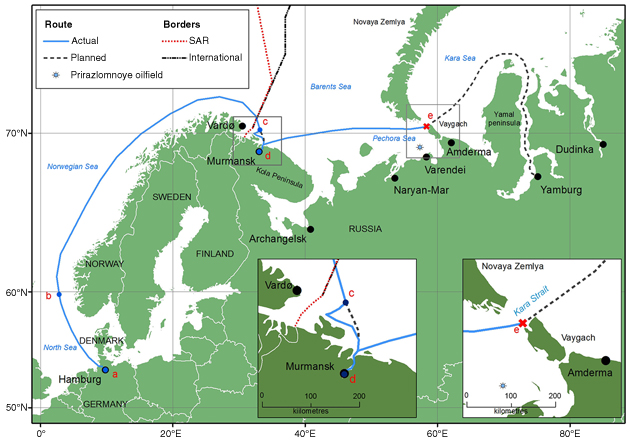

The ship is a 102 m long, 5000 dead weight tonnes multipurpose deck cargo carrier named Oleum transporting equipment from the German port Hamburg to Yamburg in western Siberia, Russia (Fig. 1). The fictitious company Kalajoki Shipping is a professional shipping company, based in a western European country. Their vessels all carry the flag of the company’s home country. Their fleet operates mainly in the Baltic and the North Sea areas. Kalajoki Shipping specializes in marine transportation of industrial dry bulk, biofuels, recyclables, minerals, forest products and different types of demanding cargo, such as heavy power plant equipment and wind turbines.

Fig. 1

The sailing route of Oleum. (a) 15 October: MV Oleum leaves Hamburg at noon. (b) The vessel sails through the North Sea, Norwegian Sea and into the Barents Sea. (c) On the night of 21 October, in Russian waters east of Vardø, the main engine stops. The auxiliary engine is started. The vessel drifts towards the Kola Peninsula. The technical failure is found and the engine restarted. (d) Early on the morning of 22 October, Oleum arrives in Murmansk. On 23 October, she leaves Murmansk for Yamburg. (e) At 08:30 on 25 October as she enters the Kara Strait, the engine stops again. Wind and currents push the vessel rapidly in the direction of the rocky shore of Vaygach Island, where she finally is wrecked.

Fig. 2

Containers breaking up and releasing cargo. From the wreck of MV Rena, off New Zealand, October 2011. Photograph courtesy of Maritime New Zealand.

The vessel has ice class 1A and can therefore navigate without ice-breaker assistance in the western part of the NSR—the Kara Sea—during periods defined as having light ice conditions. Her fuel storage capacity is 220 tonnes of MDO, 50 tonnes of diesel oil and 8 tonnes of lubricant oil. The daily fuel consumption is 11 tonnes of MDO at a cruising speed of 11 knots and 7 tonnes at a speed of 8 knots. The normal crew size is 16. The port of Yamburg is a shallow river port, which Oleum can enter as her sailing draught is 4.7 m. Oleum’s cargo consists of one 750-tonne heavy propane compressor module and 24 containers, each 20 feet in length, stored on deck. The payload of the containers consists of equipment, spare parts and 130 tonnes of chemicals for petroleum drilling operations. The chemicals include standard chemicals applied in drilling operations, like fluid loss controllers and emulsifiers.

The time of sailing is late October 2014. September and October is the time of the year with the northernmost location of the Arctic sea ice. The Kara Sea is the westernmost part of the NSR passing north of Siberia, and October is the last month during which ice-pilotage is non-mandatory here. Autumn also represents a period with harsh climate conditions and an approaching winter. The time of the voyage is therefore characterized by decreasing daylight, declining air and water temperatures and increasing risk of icing on the vessel’s hull and superstructure.

Sailing route and incidents

The port of Yamburg is closed for non-Russian vessels. The voyage therefore requires both permission from the Russian government to enter the port and permission from the Russian NSRA to enter the Kara Sea. The cargo owner is a Russian gas company and, as would be normal procedure, they have already obtained permission to enter Yamburg Port before Oleum departs from Hamburg. The NSRA permitted the vessel to sail without escort and without an ice pilot. As Yamburg Port has no customs facilities, customs clearance takes place in Murmansk. The technical inspection prior to entering the NSR area was also carried out in Murmansk. An international marine insurance company based in Oslo, with representatives in Murmansk, insures Oleum and her cargo.

Oleum leaves Hamburg at noon on 15 October and follows the planned route towards Yamburg (Fig. 1). She travels from Hamburg through the North Sea, Norwegian Sea and into the Barents Sea using ordinary shipping lanes. The average speed is 10 knots with daily fuel consumption of 10 tonnes of MDO. After six days, Oleum passes Vardø, northern Norway, and sets course directly towards Murmansk. The weather has gradually worsened and a heavy wind of 20 m/s is blowing from the north-east. The air temperature is 1°C and the sea temperature is 5°C. The vessel receives large waves on its port side, but the captain considers navigation safe.

Shortly after midnight on 22 October, the engine alarm goes off. Ten minutes later the two main engines stop simultaneously. The auxiliary engine is started to keep the bow against the wind and to reduce the drift, but it provides insufficient thrust. The wind causes the vessel to drift south-west towards the Kola Peninsula at a speed of 3 knots (Fig. 1). The water depth is 230 m, which is too deep for use of the anchor. At 00:45, Oleum calls for emergency assistance using VHF. The request is picked up simultaneously by the coastal radio stations in Vardø and Murmansk and is passed on to the rescue coordination centres in Bodø (Norway) and Murmansk. The position, provided by the vessel’s own GPS navigation system and the Automatic Identification System, an automatic tracking system used on ships, is transferred to the rescue coordination centres. Murmansk Rescue Coordination Centre leads the rescue operation and directs a nearby trawler to the area. The Russian border service agrees to send one of their patrol vessels towards the disabled ship. It might reach Oleum within 1.5 hours. The Murmansk Shipping Company also agrees to direct a nearby navigating ice-breaker towards Oleum’s position, potentially reaching the scene within three hours.

The crew of Oleum manages, however, to restart the engines without assistance after discovering the cause of the engine failure. Clogged fuel filters blocked the fuel supply. After changing the filters, the engines run smoothly and Oleum continues her journey.

In Murmansk, customs authorities and a specialist from Murmansk Port authorities, representing the NSRA, inspect Oleum. Simultaneously, the vessel’s engineers run comprehensive checks and tests of the engines to secure that they run smoothly under varying workloads. The captain reports the identified reason for the incident to the NSRA inspector and assures that extra measures are taken to keep an eye on the fuel filters. The vessel is considered fully seaworthy. Customs clearance and necessary permissions for the cargo and for entering the NSR are in place. Oleum leaves the port of Murmansk at 05:30 on 23 October and heads for Yamburg. In the evening of 24 October, Oleum enters the Pechora Sea. She heads towards the Kara Strait between Novaya Zemlya and Vaygach (Fig. 1). There is no sea ice. The vessel reports its position and speed to the NSRA every day at 12:00 using Inmarsat-C SafetyNET, a maritime mobile satellite system.

In the early morning of 25 October, Oleum is north-west of Vaygach, and the weather suddenly worsens. The wind becomes stronger, 20 m/s from the north-east, with rain and the air temperature drops to −3°C. Oleum is struggling in heavy waves and a cover of ice starts to build up on her bow and superstructure. As she enters the 56 km wide Kara Strait, both main engines suddenly stop again at 08:30. The source is again identified as clogged filters and new filters are rapidly installed. The engines restart but run only for a few minutes before they stop again as the filters continue to be clogged. The engineers now realize that both fuel tanks are heavily contaminated, and they are unable to prevent the coagulating fuel from entering the filters.

At 09:00, the wind and currents rapidly push the vessel in the direction of the rocky shores of Vaygach, 30 km away. Once again, the auxiliary engine is started in an attempt to help stabilize the vessel and to slow down the drift, but the power delivered is insufficient to prevent the vessel from drifting. The icing of the vessel continues, particularly on the bow section. An attempt to drop the anchors as an emergency procedure fails as both anchors are encapsulated in solid ice. The anchors are not manually accessible by the crew under the present conditions. The nearest seaport with regular SAR and OSR facilities is Arkhangelsk, 1000 km to the south-west of Oleum’s current location. At 09:45, the captain sends distress signals through the coastal radio and hopes for available rescue resources at Amderma, the river port Naryan-Mar, the nearby Varandey oil terminal or the Prirazlomnaya oil production platform (Fig. 1). Amderma is primarily a military settlement located 120 km south-east of Oleum’s distress location. The coastal radio responds and the Murmansk Rescue Coordination Centre takes control of the coordination. Amderma and Naryan-Mar both report no suitable vessels for a rescue operation available, but Amderma reports two military helicopters ready for take-off as soon as the weather permits. These are suitable for transport but do not have equipment for sea rescue operations. Varandey airport does not have helicopters available. Naryan-Mar hosts one helicopter, which is ready to take off as soon as the weather permits.

At 11:30, an ocean-going tug leaves the Varandey terminal and an atomic ice-breaker breaks off from its cruise in the Kara Sea some 350 km east of the Kara Strait. Nearly three hours after the engine stopped, help is still far away. Oleum hits the rocky shores on the eastern side of Dolgaya Bay on Vaygach Island (Fig. 1). The vessel is lifted onto the beach and ends up on a shallow, rocky seabed. The intense pressure forces the vessel into a 40-degree list to the starboard side. The weight of the compressor nearly capsizes the vessel. Most of the containers cannot withstand the stressful conditions and loosen from their attachments points. Sixteen containers slide sideways off the deck and hit the sea and the cliffs. Four containers are ripped open and large volumes of chemicals stored in cans, drums and bags are released into the sea (Supplementary Fig. S1) and along the shore. The remaining eight containers are unstable on deck. The vessel finally rests at an angle of about 25 degrees. Shortly afterwards, diesel fuel starts to leak. One of the ballast water tanks is also leaking. The crew prepares to abandon the vessel, but hesitate because of the dangerous conditions. They stay on board awaiting assistance.

At 14:30, the weather starts to calm and wind speed reduces to 11 m/s. This allows the two military helicopters to take off from Amderma. They circle over Oleum 30 minutes later and land on Vaygach Island, waiting for the SAR helicopter from Naryan-Mar. At 15:30, the SAR helicopter arrives. Flight time has been 1.5 hours, but as weather conditions first improved in the west, the crew managed to take off 30 minutes earlier than the helicopters from Amderma. The helicopter proceeds immediately to lift the crew from the vessel and place them on the shore. The operation is successful and takes about 25 minutes. The crew is brought to Naryan-Mar by the awaiting military helicopters, and the rescue operation is completed.

At 16:45, the ocean-going tug arrives the scene. It has OSR equipment on board, and starts to launch booms near Oleum to confine as much of the spilled oil, debris and chemicals as possible around the wreck. However, the booms are not long enough to cover the entire bay, leaving uncovered gaps. In addition, floating containers on the surface represent a risk of collision and further spills. Approaching darkness halts the operation at 17:00.

The atomic ice-breaker arrives at 22:20. It is dark, but the weather is now calm. The ship has both trained OSR personnel and OSR equipment on board, but the captain cannot manoeuvre the large vessel into the narrow bay. Instead, booms are launched outside the bay, and towed into the bay by two small motor boats. Supported by strong spotlights from the ship, the work is conducted throughout the night and both the wreck of Oleum and the entrance of the bay are sealed. The motor boats hook up floating containers and tow them to shallow water in the bay. The next morning a platoon of navy engineers is brought to the bay by the helicopters from Amderma. Using the light vessels, they provisionally succeed in keeping the floating containers moored at the shore in shallow water using wires and hooks.

In the meantime, an OSR vessel from the Marine Rescue Service under the Ministry of Transport from Murmansk and a rescue vessel from the Ministry of Emergencies from Arkhangelsk steam towards Vaygach Island. As pointed out in the Arctic Marine Shipping Assessment study, the distances in the Arctic are large (Arctic Council 2009), and sailing time for the vessels is expected to be 44 and 52 hours, respectively. The two ships arrive during 28 October in good weather conditions. The OSR vessel immediately starts to recover oil and spilled chemicals. The rescue vessel is assisted by a reinforced ice-class container-ship, deviating from its voyage from Murmansk to Dudinka. This vessel belongs to a mining company and is equipped with two 40-tonne cranes designed to load and unload cargo in areas outside dedicated ports. It attempts to salvage the containers but the captain soon finds the operation too dangerous and complicated. He therefore aborts the operation and the vessel leaves the scene.

Discussion

To identify the technological and infrastructural gaps for safe maritime operations in this area requires, first, an understanding of Arctic conditions, such as harsh weather, icing, sea ice, low visibility, darkness and low temperatures. One also needs to understand what kind of equipment typically is installed and used on board the vessels, and the need for supporting technology, infrastructure and external aid during critical situations. Below we point out some of the technological and infrastructural gaps highlighted by the fictional Oleum accident.

SAR and emergency preparedness operations

SAR operations in Arctic waters are challenging. Low sea and air temperatures reduce the survival time for persons in water or on ice. The probability of finding persons alive depends on the following factors: response time for the SAR resources; quality of initial position datum of a missing person; models for drifting motion of live saving equipment and persons in the sea; quality of technology based search systems and application of pre-defined search patterns; training of human lookouts on ships, helicopters and airplanes; and on site weather (waves, wind, temperature in sea and air, precipitation and fog) and light conditions (day/night, summer/winter). Because of the low traffic density in Arctic waters and large distances between dedicated emergency response resources, all users of Arctic waters have to focus on self-rescue as an important part of their safety management strategy. Establishing a buddy system with other vessels in the same waters is also advisable, and so-called voyage pairing has been discussed by the International Maritime Organisation (IMO 2006). Finally, the ships’ crews should notify immediately when they are experiencing operational irregularities.

The Arctic states approved the Arctic SAR agreement in May 2011 (Arctic Council 2011). It entered into force on 19 January 2013. This agreement divides the Arctic into five geographic regions, in which each of the five Arctic states—Russia, Norway, Canada, USA and Greenland/Denmark—holds the responsibility for coordination SAR operations. Oleum’s first trouble occurred near the Norwegian–Russian SAR border in the Barents Sea, which in this area runs in parallel with the international border (Fig. 1). Here, systems for close information exchange between traffic monitoring centres in Vardø and Murmansk are established.

The Russian Ministry of Emergencies plans to build 10 emergency rescue centres in the Arctic that will facilitate rescue and emergency operations in remote places. The creation of these centres is a part of a government targeted programme approved in 2011 (Federal Targeted Programme 2011). In August 2013 the first rescue centre was opened in Naryan-Mar. By 2015, four such centres were opened: Naryan-Mar, Murmansk, Vorkuta and Dudinka, the latter far east of the Kara Strait. In the scenario, the rescue helicopter arrives from the Naryan-Mar rescue centre, located slightly closer to the accident site than Vorkuta.

The Oleum scenario is partly based on the rescue of the Norwegian fishing vessel Kamaro in late October 2012. Because of a technical failure, Kamaro lost engine power in the Barents Sea in strong wind and waves up to 15 m. Coming to assist, another fishing vessel passed a towline to the Kamaro and started towing her towards the Norwegian coast. Still in open sea, the Norwegian coast guard vessel KV Harstad arrived and took over the emergency tow. Approaching the Norwegian coast, the motion of Kamaro grew violent and it was feared that the towline was going to break. It was therefore decided to evacuate the crew of 14 off Kamaro using the coast guard vessel’s helicopter. During the first attempt to lift the crew from the vessel, one of the hoist’s lift wire snagged in the vessel’s equipment and was damaged. It was then decided that the crewmembers had to jump into the sea to be picked up by the helicopter. The towline between Kamaro and Harstad broke before the last two crewmembers jumped overboard; however, all crew members were rescued. Two coast guard vessels followed the drifting Kamaro until it was safe to re-establish the emergency towing line in calm waters closer to the coast.

Supporting technologies and infrastructure

Ensuring safe maritime operations includes: (1) detecting and avoiding dangerous situations; (2) managing unplanned incidents properly when they occur; (3) ability to communicate and receive external assistance from emergency response and SAR resources. Human resources, technologies and infrastructure are all required for safe navigation. In the case of Oleum, the crew of 16 persons consisted of the basic crew for operating the vessel. Granting an exemption because the passage was scheduled for the ice-free period, the NSRA permitted the ship to sail into the NSR area without an ice pilot on board.

The equipment and technology installed on-board vessels operating in Arctic conditions are regulated by both international and coastal state rules. The main regulations concerning equipment and on-board technology for the NSR are reflected in these documents: “Requirements for vessels navigating the NSR” (NSRA 1996); “Annual communication recommendations,” issued by the NSRA for 2013–14 (NSRA 2013) and by the Federal Agency of Maritime and River Transport for 2012–13 (Rosmorrechflot 2012). These documents state that navigation and communication equipment installed on board—in particular the Global Maritime Distress Safety System—must meet the requirements set forth in international conventions like the International Convention for the Safety of Life at Sea and International Convention for the Prevention of Pollution from Ships as well as the rules of the Russian Maritime Register of Shipping, recommendations from international classification societies like Lloyds or Bureau Veritas. Indeed, the Oleum was able to communicate and attract attention when struck by engine failure, but still external contingency resources were too far away to save the vessel.

The equipment supporting safe maritime operations includes equipment to detect obstacles, in order to avoid collisions, and to detect technical malfunctions of the vessel. Examples of obstacles are sea ice, fixed or floating installations and other vessels. Technologies such as radars and the Automatic Identification System are used for local detection of such obstacles. In addition to the equipment on board, navigational and meteorological–oceanographic warnings should be received from a vessel traffic service established by port authorities, similar to air traffic control, and/or coastal radio stations. Satellite images and updated ice charts are also available upon request. Sensors on machinery and the hull will detect potential failures of machinery and instability of the ship. Lacking sensors that could have provided warnings about the clogged filters before they led to engine failure, the crew of Oleum did not have the possibility for early action. During the second engine failure, Oleum was also exposed to heavy icing, depriving the crew of the possibility to drop the anchors and stop her drifting. However, to what extent early warning of hull icing could have prevented the accident is uncertain.

Important supporting technologies for safe maritime operations, including SAR operations, are navigation and communication technologies (Kvamstad et al. 2009), primarily global navigation satellite systems and satellite-based and terrestrial communication systems. GPS navigation satellites and the Russian global navigation satellite system are available aids in the Barents Sea, although the signals can be irregular and obstructed because of low elevation angles of the satellites. In acute maritime operations the accuracy and timing requirements are so high that additional integrity information from GPS is required. The information is not delivered by the navigation satellites themselves, but either via on-shore reference stations or satellite-based augmentation systems. The availability of reference stations is low in the Barents and other Arctic seas, and satellite-based augmentation systems are based on GEO, which orbit the Earth around the equator. These have limited availability at latitudes above 75°N. Field tests performed in the MarSafe North project (Fjørtoft et al. 2009) showed that practical communication problems can be experienced already at 70°N, depending on ionospheric and weather conditions (Behlke et al. 2012). Many maritime communication systems are also based on GEO satellites, using Inmarsat and very small aperture terminal systems, so they also face the challenges of low elevation angles. The Arctic holds few and scattered coastal radio stations. The only satellite-based system that covers the polar areas is Iridium. Iridium is suitable for non-critical voice communication and transmission of short messages with low timing requirements. In the case of Oleum, sailing at 70°N, near the edge of GEO satellite coverage, the first incident happens within the coverage area of the coastal radio station in Vardø. The second incident happens in an area with limited coverage by coastal radio stations.

A vessel in distress strongly needs communication abilities. This can be achieved either via VHF DSC to the coastal radio stations or via Inmarsat-C or Inmarsat Fleet33, which is based on GEO satellites, or by activating the on-board emergency position-indicating radiobeacon station or a similar SAR transponder. The signals from on-board emergency position-indicating radiobeacon stations and SAR transponders are picked up by Cospas–Sarsat satellites. Cospas–Sarsat satellites consist of both GEO satellites and low Earth orbit satellites in near polar orbits, making this system accessible at high latitudes, including the Barents Sea. With the COSPAS-SARSAT low Earth orbit system, the time that elapses between a vessel sending a distress signal in the Arctic, and a rescue coordination centre receiving an alarm may be up to one hour.

In addition to having the technical equipment itself, access to metocean (including ice) information and navigational warnings are important in order to detect potentially dangerous situations. This information is broadcasted by the coastal radio stations and via VHF, HF/MF or Inmarsat. Since the coverage from these radio and satellite systems varies in the different regions of the Barents Sea, availability of updated information varies in both time and space.

Environmental setting and fate of the ship and her cargo

The wreckage site (70.05°N 61.75°E) is approximately at the same latitude as northern Norway and the Kola Peninsula. The sun is above the horizon for approximately seven hours in late October, but below the horizon all day in late November. Weather conditions in the Kara Sea can be harsh in late October. In our scenario, the ambient air and water temperatures were around zero, and the combined temperature and wind were contributing factors in the chain of events leading to disaster. The area is normally free of sea ice in October and in late November the Kara Sea starts to freeze over. There is often sea ice in the Kara Strait in December, as was the case in 2014 (Met 2015; Supplementary Fig. S1). The rescue and clean-up operation in this scenario therefore had to be hurried, as the waters were expected to be free of sea ice for only about one month after the stranding. In 2014, sea ice started to form in early December and by the end of the month open drift ice prevailed, with a coverage of 40–70% of the sea area (Supplementary Fig. S1).

The first attempt to recover Oleum’s floating and stranded containers failed. Any new operation needs to firstly find out whether a barge with sufficient lift capacity is within reachable distance and whether an operation can be completed within approximately one month. The time scale of about one month might be sufficient to handle containers if the operation runs smoothly. However, because of the remoteness of the site, the scenario infers that the containers have to remain on the site though the winter.

The 750-tonne heavy propane power generator is considered lost. There are only a few floating devices available worldwide which have the capacity to lift 750 tonnes in one piece. The Oleum wreck is stranded on a shallow rocky beach, making access from the sea difficult for any lifting vessel. The generator can therefore not be retrieved in one piece. Disassembling the power generator is a time-consuming process which needs to be postponed over winter.

The leakage of MDO and chemicals behaving like oil was handled with booms and skimmers. No assistance from abroad was engaged since the manager of the response operation considered Russian domestic OSR equipment, which was closest to the location of the wreckage, sufficient (see article 8 of the 2013 Marine Oil Spill Cooperation agreement [Arctic Council 2013]). In our scenario, some of the spilled oil and chemicals was retrieved, some evaporated and some dispersed to the seawater, consistent with observations of an accidental MDO spill in Skjervøy harbour (70.03°N 20.97°E), northern Norway, in December 2013. In Skjervøy, approximately 25% of the spilled diesel (48°000 of 180°000 litres) was mechanically recovered (Sagerup & Geraudie 2014) and diesel fumes were detectable for weeks in the part of town adjacent to the harbour. The total hydrocarbon concentration recorded at 20 cm water depth five days post-spill was 3.5 mg/l, showing that some of the marine diesel had dispersed in the seawater (Sagerup & Geraudie 2014).

Oil and chemical spills

The physiochemical behaviour of chemicals spilt at sea is the single most important factor for the development of a response strategy and response plan. The European Behaviour Classification system (Bonn Agreement 2006; Neuparth et al. 2012) describes the theoretical behaviour of a substance and classifies it into four families: evaporators, floaters, sinkers and dissolvers. A normal behaviour of oil and oil-like products spilled into sea is that three fractions are formed. One part of the oil evaporates, one part floats and some of the oil dissolves in water. Under the influence of ambient water temperature, wind, waves and currents, the evaporation and dissolution processes can be accelerated or delayed. When a chemical is spilled, the choice of response strategy depends on the accident area, the containment of the chemical and the behaviour of the product. The Oleum accident site is remote and the scenario includes chemicals lost overboard, chemicals still in containers on deck and chemicals lost from individual packages discharged from ruptured containers (Fig. 2). To secure the health and security of the salvage crew, knowledge of the properties of the chemicals released is essential. However, with the containers astray, any such information in the vessels logbook is considered unavailable to the crew and managers of the clean-up.

The only available mechanical clean-up technology at sea is booms and skimmers designed to handle oil at the sea surface. The booms that were launched around Oleum to prevent oil from spreading also collected debris and floating chemicals that did not dissolve in the water. Some of the chemicals transported are oil-soluble and float (Supplementary Table S1). Generally behaving like oil on the water, these chemicals will mix with the spilled oil and will be collected as the oil-chemical mixture is skimmed from the sea surface. A chemical that evaporates, dissolves or sinks cannot be mechanically recovered from the sea surface. The two non-oil-like substances of Oleum’s cargo either dissolve (2,4,5-trifluorobenzoic acid) or sink (BDF-513; Supplementary Table S1). The acid will quickly dissolve in water. BDF-513 has a higher density than water, is insoluble and will therefore sink. It will spread over a smaller or larger area depending on the ambient conditions, and can theoretically be collected by dredging or be left in place.

Potential effects

Every winter, the coastlines of the Kara and Pechora seas are scoured by drifting sea ice, which reduces the diversity and abundance of sessile organisms in the littoral and sub-littoral zones. The benthic faunal assemblages down to 10 m water depth are evaluated as not particularly vulnerable to oil pollution (Kulakov et al. 2006). Drifting eggs and fish larvae cannot swim effectively, but move passively with the water currents. They can therefore be highly influenced by oil and chemical pollution in the water column. Marine mammals and, especially, seabirds are vulnerable to oil pollution (Kulakov et al. 2006).

The chemicals in the scenario have three different physiochemical properties. The oily chemicals will principally have the same kind of effect as oil. The floating part will attach to feathers and fur and the primary effect is heat loss and/or a direct toxic effect. The longer term effects of these chemicals will be related to the chemical composition, which is often a commercial secret (Supplementary Table S1). The toxic effect of oil and oil-related products are often related to which compounds within the PAH group they contain. PAH compounds have a range of direct and indirect toxic effects and some PAHs accumulate in biota (van der Oost et al. 2003; Albers 2006; Manzetti 2013).

The three oil-soluble chemicals—Versavert PE, Test-WT-14 and the CDR Liquid Power Flow Improver (Supplementary Table S1)—are classified into the yellow, red and black environmental toxicity categories, respectively, in accordance with the HOCNF, a classification system applied in Norway, among other countries. CDR has the highest potential environmental risk, but detailed information about this chemical and its HOCNF test results are not publicly available. Information regarding the silicone compound Test-WT-14, in the red category, is also secret. Some information is available for Versavert PE, in the yellow category. It contains a toxic solvent that is easily degraded, but has a low toxicity to marine organisms and has a low potential for bioaccumulation (Supplementary Table S1).

The crystal-powdered acid (2,4,5-trifluorobenzoic acid) will dissolve in seawater. It will be diluted and spread in the water column. The chemical itself is toxic, but it has low bioaccumulation potential (Supplementary Table S1). The effect of the acid is dependent on the amount spilled, release rate and time of the year. Since the scenario describes a sudden release of large quantities, a sudden acidification of the water is expected. The expected effect at the grounding site will therefore be extensive but short-lived. Plankton, larvae and fish in the affected area will be exposed and some die-off of benthic organisms is expected. As the currents flush clean water into the area, the acid will be buffered and the pH will return to normal.

The chemical BDF-513 is a powder with low water solubility. It is denser than water and will thereby sink when spilled into the sea. Besides the option of not taking any actions, there are two ways to remedy a spill of this kind of substance: mechanical recovery using a dredge or grab or leaving it in place, with or without adding a cover of clean gravel. Bearing in mind the rough sea-ice conditions influencing the coastline, a likely outcome is that the substance will spread out across a large area during winter, making handling during the coming summer season difficult. BDF-513 is in Norway classified as red. The specific ingredients in the compound are not publicly available, but an Australian study (NICNAS 2010) has indicated both low toxicity and low risk of bioaccumulation.

None of the chemicals transported by Oleum in the scenario are currently permitted for use in Russia since their maximum permissible concentrations have not yet been set (Bambulyak et al. 2014). However, as the chemicals are widely applied in petroleum operations worldwide, these are included in the current scenario for illustration purposes. Applications for use in Russia are foreseen, and those chemicals should be approved for use based on “maximum permissible concentrations” (depending on recipient water body) (Bambulyak et al. 2014).

Spilled oil and floating debris affect marine life. Populations of plants and animals vary in distribution and abundance through the year, so the impact of an oil spill in a particular area will also vary with season. The environmental sensitivity of the Vaygach area has been evaluated for potential offshore petroleum activity and potential oil spills (Pogrebov & Puzachenko 2001). This evaluation concludes that the Pechora Sea–Kara Strait coastal ecosystem is most vulnerable in spring, when plankton blooms, migrating birds return and seals come to breed. It is well documented that migrating birds leave the Kara Strait area in the autumn, but there are large gaps in our knowledge of the annual distribution and abundance of marine organisms, especially for the Kara Sea (Kulakov et al. 2006).

Post-spill monitoring

When a major spill of oil or chemicals occurs, a programme for post-spill environmental monitoring is developed and implemented with the aim of assessing any long-term environmental effects, and monitoring ecosystem recovery (Dahle et al. 2011; Boitsov & Klungsøyr 2012; Jørgensen et al. 2012). Surveys and sampling should be organized so that major ecological changes can be detected, assessed and evaluated. For the Oleum case, it is anticipated that the post-spill monitoring will include the collection and analyses of samples to determine the presence of oil along the beaches and the BDF-513 substance on the sea bottom. Benthic fauna should be sampled and analysed for oil and chemicals. A wildlife-monitoring programme should include searches for dead fish, mammals and seabirds, with subsequent autopsy and chemical analysis to determine cause of death. Lastly, a biosecurity survey could address whether new and unwanted marine organisms have entered the environment via the lost ballast water or the exterior of the hull (Ware et al. 2012).

Learning outcome

As a vessel moves eastward from the Barents Sea to the Pechora and Kara seas, the distance to populated areas and available communication, SAR and OSR resources increases. The distances pose challenges for SAR and OSR operations. In the scenario we present here, the crew members were rescued and parts of the propulsion fuel and parts of the cargo were cleaned up. Rescue of the ship’s crew is always the prime objective of SAR. OSR actions are aiming at recovering oil; corresponding measures to handle unknown quantities and compositions of spilled chemicals are not generally available. Containers holding cargoes of unknown danger class, origin and amount are off limits for traditional rescue and OSR operators.

A lesson learned from the large container vessel Rena grounding in the Bay of Plenty, New Zealand, on 5 October 2011, was that mobilization of proper equipment, unloading of containers and clean-up of scrap metal and debris take time, even in a favourable subtropical climatic setting (Rena Recovery Project Team 2015). The time from the onset of the Oleum accident until sea ice starts to form in this area is about one month. This is not enough time to recover the wreck itself, the 750-tonne power generator and containers, which most likely will be left over winter, provisionally anchored at the stranding point. The forces of sea-ice flow and ocean currents will affect all items remaining on site. This might result in the release of more chemicals and debris during winter and spring as the containers are worn down.

The Arctic Council has established several working groups addressing safety and environmental safeguarding within human activities in the Arctic. Policy issues are addressed by the Protection of the Arctic Marine Environment working group, while the Emergency Prevention, Preparedness and Response working group addresses aspects of environmental emergencies in the Arctic. Their goal is to contribute to the protection of the Arctic environment against the threat or impact that may result from an accidental release of pollutants, including radionuclides. The Emergency Prevention, Preparedness and Response workshop in June 2012 concluded that we are insufficiently prepared for an incident involving a large container vessel (Arctic Council 2012). The workshop recommended that “a Risk Analysis for the Arctic should be carried out” and that the risk analysis should include a worst case scenario with a container vessel to improve our understanding of current and future environmental risk of shipping in the Arctic.

The potential effects of the spilled chemicals are threefold. The three oil-soluble chemicals are generally expected to expose and affect biota in a similar manner as oil. However, they will gradually break down physically and biologically. Released just before the sea ice forms, the oil and chemicals may be trapped in ice, to be carried away and released at another time and in another area when the ice melts. 2,4,5-Trifluorobenzoic acid will have a quick and strong effect in a limited area, but as soon as it is diluted, the effect will disappear. The BDF-513 seems not to pose any short-term effect as it has low toxicity and it is not expected to bioaccumulate. However, the long-term effect is unknown.

The fictive travel of Oleum, combined with experience from accidental events globally, indicates major challenges in Arctic navigation, SAR and OSR, and also points towards insufficiencies in our ability to predict the extent of environmental impacts of accidental discharges. Recovering container-transported cargo lost at sea is difficult under favourable circumstances; winter recovery operations in remote, poorly charted parts of the Arctic are considered close to impossible.

Oleum was a fictitious vessel on a fictitious voyage in the Arctic. The presented chains of events illustrate the wide variety of challenges needing attention when planning, performing and understanding the environmental impacts of Arctic navigation.

Acknowledgements

The MV Oleum scenario is part of A-LEX: Regulating Arctic Shipping—Political, Technological and Environmental Challenges, a Fram Centre research project funded by the research flagship programme Sea Ice in the Arctic Ocean, Technology and Agreements, the Norwegian Ministry of Foreign Affairs and the NORRUS programme of the Research Council of Norway. The authors would like to thank Chris Emblow for providing language advice and drafting Fig. 1, and Brage Mo, Anders Valland, Dag Stenersen and Ingebrigt Valberg for assistance in developing a relevant scenario for the machinery failures.

References

Albers

P.H. 2006.

Birds and polycyclic aromatic hydrocarbons. Avian and Poultry Biology Reviews 17,

125–140.

Publisher Full Text

Arctic Council 2009. Arctic marine shipping assessment 2009 report.

Tromsø: Arctic Council.

Arctic Council 2011. Agreement on cooperation on aeronautical and maritime search and rescue in the Arctic. Accessed on the internet at https://oaarchive.arctic-council.org/handle/11374/531 on 8 April 2016

Arctic Council 2012. Report from EPPR workshop on emergency prevention, preparedness and response in Kirkenes, Norway. June 5–7, 2012.

Tromsø: Arctic Council.

Arctic Council 2013. Agreement on cooperation on marine oil pollution preparedness and response in the Arctic. Accessed on the internet at https://oaarchive.arctic-council.org/handle/11374/529 on 8 April 2016

Bambulyak

A.,

von Bock und Polach

R.U.F.,

Ehlers

S.

&

Sydnes

A.K. 2014. Challenges with oil spill risk assessment in arctic regions: shipping along the Northern Sea Route. In: Proceedings of the 33rd International Conference on Ocean, Offshore and Arctic Engineering. Vol. 4b. Structures, safety and reliability. Paper no. OMAE2014-2441, doi: http://dx.doi.org/10.1115/OMAE2014-24419.

New York: ASME Press.

Behlke

R.,

Kvamstad

B.,

Bjørdal

E.,

Lorentzen

D.

&

Sigernes

F. 2012. Maritime radio system performances in the high North (MARENOR). Paper presented at the International Emergency Management Society Conference. 22–24 October, Oslo.

Boitsov

S.

&

Klungsøyr

J. 2012. Undersøkelser av hydrokarboner i sedimenter fra MAREANO-området 2010. (Survey of hydrocarbons in sediments from the MAREANO area 2010.) Report 11-2012.

Bergen: Institute of Marine Research.

Bonn Agreement 2006. Hazardous materials. In Bonn agreement counter-pollution manual. Pp. 112–132.

London: Bonn Agreement.

Dahle

S.,

Larsen

L.-H.,

Bambulyak

A.

&

Studenov

I. 2011.

Norwegian–Russian cooperation on reducing environmental risk of accidental oil spills on Arctic coasts.

In A. Bourmistrov et al. (eds.): Perspectives on Norwegian–Russian Energy Cooperation. Pp. 147–159. Oslo: Cappelen Damm.

Duinker

P.N.

&

Greig

L.A. 2007.

Scenario analysis in environmental impact assessment: improving explorations of the future. Environmental Impact Assessment Review 27,

206–219.

Publisher Full Text

Federal Targeted Programme 2011. Reducing the risk and mitigating the consequences of natural and man-made emergencies in the Russian Federation up to 2015. Approved by the Government of the Russian Federation, Resolution no 555, 7 July 2011.

Fjørtoft

K.,

Kvamstad

B.

&

Bekkdal

F. 2009.

Maritime communication to support safe navigation.

In A. Weintrit & T. Neumann (eds.): Marine navigation and safety of sea transportation. Pp. 285–291. London: Taylor & Francis.

IMO 2006. Enhanced contingency planning guidance for passenger ships operating in areas remote from SAR facilities. Maritime Safety Committee Circular 1184.

London: International Maritime Organization.

Jørgensen

N.M.,

Camus

L.,

Larsen

L-H.,

Vögele

B.,

Skeie

G.M.,

Spikkerud

C.,

Anker-Nilssen

T.,

vanDijk

J.,

Lorentsen

S.-H.,

Stabbeltorp

O.,

Bjørge

A.,

Boitsov

S.

&

Klungsøyr

J. 2012. Retningslinjer for miljøundersøkelser i marint miljø etter akutt oljeforurensning. (Guidelines for environmental monitoring after acute oil spill in the marine environment.)

Guideline no. TA 2955.

Oslo: Norwegian Environmental Authority.

Kulakov

M.Y.,

Pogrebov

V.B.,

Timofeyev

S.F.,

Chernova

N.V.

&

Kiyko

O.A. 2006.

Ecosystem of the Barents and Kara seas, coastal segment.

In A.R. Robison & K.H. Brink (eds.): The global coastal ocean: interdisciplinary regional studies and syntheses. Pp. 1135–1172. New York: Harvard University Press.

Kvamstad

B.,

Bekkadal

F.,

Fjørtoft

K.E.,

Marchenko

A.

&

Ervik

J.L. 2009.

A case study from an emergency operation in the Arctic seas.

In A. Weintrit & T. Neumann (eds.): Marine navigation and safety of sea transportation. Pp. 455–461. London: Taylor & Francis.

Manzetti

S. 2013.

Polycyclic aromatic hydrocarbons in the environment: environmental fate and transformation. Polycyclic Aromatic Compounds 33,

311–330.

Publisher Full Text

Met 2015. Norwegian Ice Service. Norwegian Meterological Institute. Accessed on the internet at http://polarview.met.no/ on 10 February 2015.

Neuparth

T.,

Moreira

S.M.,

Santos

M.M.

&

Reis-Henriques

M.A. 2012.

Review of oil and HNS accidental spills in Europe: identifying major environmental monitoring gaps and drawing priorities. Marine Pollution Bulletin 64,

1085–1095.

PubMed Abstract | Publisher Full Text

NICNAS 2010. National industrial chemicals notification and assessment scheme (NICNAS). Full Public Report PLC/914.

Sydney: Department of the Environment, Water, Heritage and the Arts.

NSRA 1996. Requirements for the design, equipment and supplies of vessels navigating the Northern Sea Route.

Moscow: Northern Sea Route Administration. Accessed on the internet at http://arctic-lio.com/nsr_legislation on 19 January 2014.

NSRA 2013. Communication recommendations for the waters of the NSR 2013–2014.

Moscow: Northern Sea Route Administration. Accessed on the internet at http://nsra.ru/en/recomend_po_svyazi/ on 19 January 2014.

Pogrebov

V.B.

&

Puzachenko

A.Y. 2001.

Integral assessment of potential biota sensitivity to offshore oil-field development operations. Coastline 1,

10–11.

Rena Recovery Project Team 2015. Rena Recovery. Long-term environmental recovery plan. Accessed on the internet at http://www.renarecovery.org.nz/ on 15 March 2015

Rosmorrechflot. 2012. Communication instructions for Arctic navigation 2012–2013 on the Northern Sea Route.

Moscow: Federal Agency of Maritime and River Transport.

Sagerup

K.

&

Geraudie

P. 2014. Miljøundersøkelse etter dieselutslipp til Skjervøy havn. (Environemntal survey after a diesel spill in Skjervøy, northern Norway.)Report 6821.

Tromsø: Akvaplan-niva.

Schoyen

H.

&

Brathen

S. 2011.

The Northern Sea Route versus the Suez Canal: cases from bulk shipping. Journal of Transport Geography 19,

977–983.

Publisher Full Text

Smith

L.C.

&

Stephenson

S.R. 2013.

New trans-Arctic shipping routes navigable by midcentury. Proceedings of the National Academy of Sciences 110,

E1191–E1195.

Publisher Full Text

Stephenson

S.R.,

Smith

L.C.,

Brigham

L.W.

&

Agnew

J.A. 2013.

Projected 21st-century changes to Arctic marine access. Climatic Change 118,

885–899.

Publisher Full Text

van der Oost

R.,

Beyer

J.

&

Vermeulen

N.P.E. 2003.

Fish bioaccumulation and biomarkers in environmental risk assessment: a review. Environmental Toxicology and Pharmacology 13,

57–149.

PubMed Abstract | Publisher Full Text

Ware

C.,

Alsos

I.G.,

Berge

J.,

Sundet

J.H.

&

Arneberg

P. 2012. Ships as potential dispersal vectors of invasive marine organisms into High-Arctic Svalbard. Tromsø: University of Tromsø.